Precision machining equipment and advanced manufacturing technology are used to cut, clean, and anneal thermocouple wires. High-purity platinum, nickel, or copper resistance elements are manufactured, with precision ensured through laser cutting or precision machining.

Specialty Thermocouples:

We have developed thermocouples for use in solutions such as molten steel, copper, aluminum, and zinc, as well as in salt furnaces, and high-precision, long-life thermocouples suitable for the special environments of cement plants and power plants. Our new anti-oxidation tungsten-rhenium thermocouples are low-cost and offer high temperature measurement, making them an ideal replacement for platinum-rhodium thermocouples; some products meet military standards.

Wireless Temperature Control and Measurement:

We have successively passed ISO9001 quality system certification, ISO14001 environmental management system certification.

Explosion-proof Certification:

In 2013, we obtained national explosion-proof production qualification certificates for explosion-proof thermocouples and resistance temperature detectors (RTDs), ensuring the safety of our products in special environments.

Polytetrafluoroethylene (PTFE) Products:

Our PTFE tubes, plates, rods, gaskets, and custom-shaped parts are resistant to strong acids, strong alkalis, corrosion, and high temperatures, and are widely used in various industries, making them environmentally friendly.

-

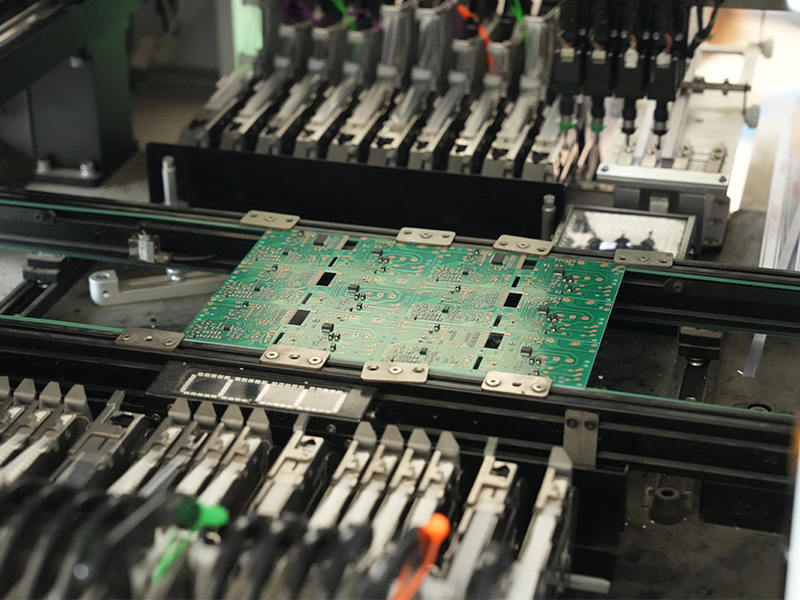

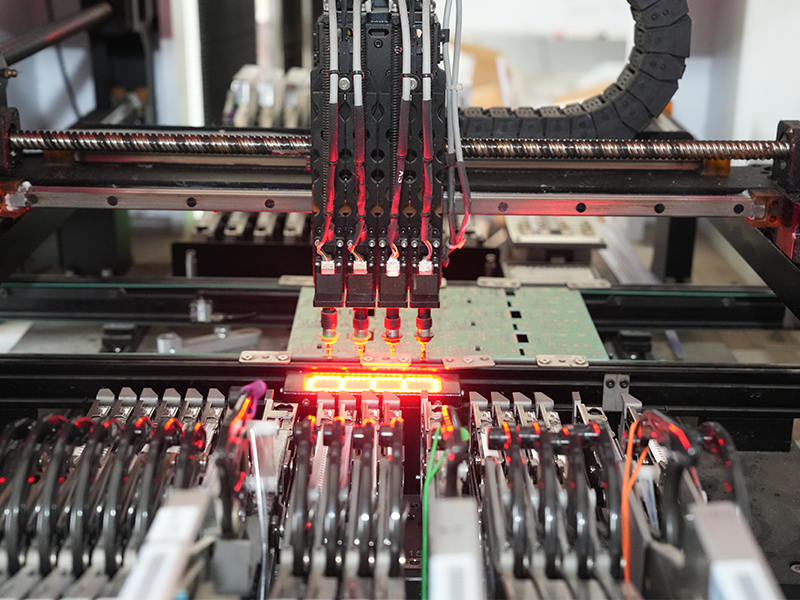

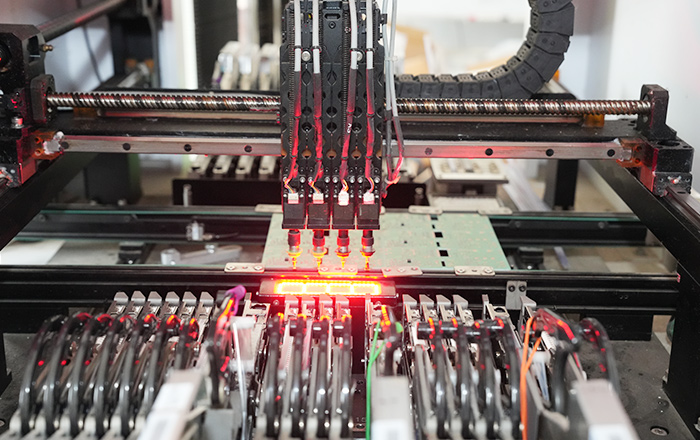

ADVANCED AUTOMATED MANUFACTURING

ADVANCED AUTOMATED MANUFACTURING -

-

01

Quality SystemWe adhere to international standards and industry norms to ensure quality at every stage of production.

Quality SystemWe adhere to international standards and industry norms to ensure quality at every stage of production. -

02

Wire ProcessingThe thermocouple wires are cut and cleaned to improve their stability and conductivity.

Wire ProcessingThe thermocouple wires are cut and cleaned to improve their stability and conductivity. -

03

Component ManufacturingManufacturing high-purity platinum, nickel, or copper resistive components, ensuring accuracy through laser cutting or precision machining.

Component ManufacturingManufacturing high-purity platinum, nickel, or copper resistive components, ensuring accuracy through laser cutting or precision machining. -

04

WeldingWelding the metal wires of different thermocouple materials together to form the temperature measuring end; connecting the resistive element to the wire and insulating it.

WeldingWelding the metal wires of different thermocouple materials together to form the temperature measuring end; connecting the resistive element to the wire and insulating it. -

05

AssemblyThe soldered thermocouple or resistance temperature detector (RTD) element is installed in a protective tube or other protective device to ensure it is unaffected by environmental factors during use.

AssemblyThe soldered thermocouple or resistance temperature detector (RTD) element is installed in a protective tube or other protective device to ensure it is unaffected by environmental factors during use. -

06

EncapsulationThe resistance element is encapsulated in a glass, ceramic, or metal tube. Thermocouples also require suitable protective tubes to ensure their durability and protection.

EncapsulationThe resistance element is encapsulated in a glass, ceramic, or metal tube. Thermocouples also require suitable protective tubes to ensure their durability and protection. -

07

Insulation and Explosion-proofingSpecial explosion-proofing treatment is applied to thermocouples and RTDs requiring explosion protection to ensure safe use in hazardous environments.

Insulation and Explosion-proofingSpecial explosion-proofing treatment is applied to thermocouples and RTDs requiring explosion protection to ensure safe use in hazardous environments. -

08

Electronic Component IntegrationThermocouples and other temperature control products jointly developed with multiple institutions in Shanghai are sold well both domestically and internationally with high cost-effectiveness.

Electronic Component IntegrationThermocouples and other temperature control products jointly developed with multiple institutions in Shanghai are sold well both domestically and internationally with high cost-effectiveness.

-

01

-

FACTORY TESTING & CALIBRATIONEach product undergoes comprehensive testing before leaving the factory to ensure its accuracy and stability within the operating temperature range. Provide regular calibration guidance, use high-precision calibration equipment and standard substances to calibrate and adjust products, ensuring accuracy during long-term use.

FACTORY TESTING & CALIBRATIONEach product undergoes comprehensive testing before leaving the factory to ensure its accuracy and stability within the operating temperature range. Provide regular calibration guidance, use high-precision calibration equipment and standard substances to calibrate and adjust products, ensuring accuracy during long-term use.- Calibration accuracy--Providing a resolution of up to 0.01 ℃

- Temperature range--Ranging from -200 ° C to+2000 ° C

- Temperature control--Temperature difference control within ± 0.1 ° C.

- Response time--Rapid response of equipment in rapidly changing temperature environments.

- Automated calibration process / Calibration certificate/standard specifications

eng

eng

English

English